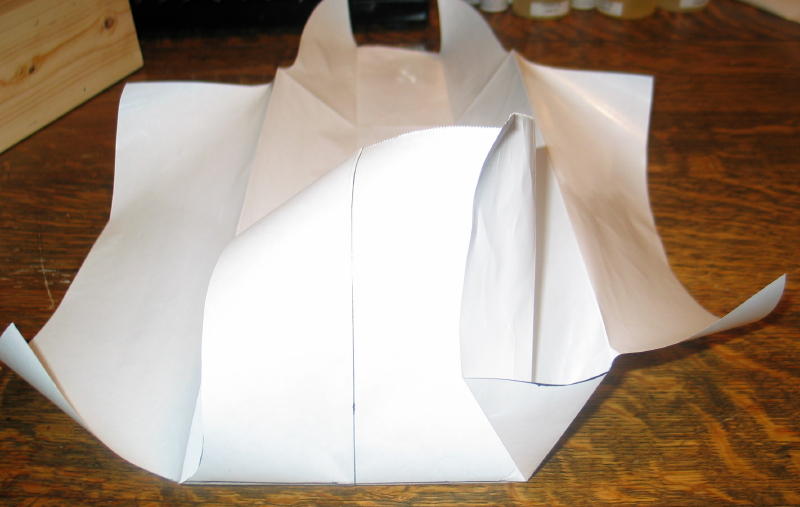

Votive candles have always been one of my favorite to burn. They are small, store easily and I LOVE votive holders! They are all over my house. A lot of people are afraid to make these, they are actually quite easy and fun! You will need the following: IGI 4794 Votive Blend 44-24-18lt1 Wicks Fragrance Dye Votive Molds Begin by melting your wax. Use either a double boiler, Presto Kitchen Kettle or a commercial wax melter.

We also offer a Votive Starter Kit

It is advisable to poke relief holes around the wick of the candle once the wax has become solid but is still pliable.

After the first pour has cooled, reheat your reserved wax from your first pour and refill the void (sink hole) in the candle until you reach the level of the first pour. You will want your second pour to be 10* hotter than your first pour to minimize lines from the second pour. Repeat the repour process as necessary.

Give the candles at least a few hours to cool down. I usually wait overnight and remove the next day. If they are hard to get out of the molds, you may want to put them in the freezer for a few minutes. You may also find for the first few times you use a new mold you will need mold release. The spray and powder form both work excellent in this wax.

Happy Candlemaking!

Flicker

Flicker